Tailor rolling of High Strength Aluminium Alloys

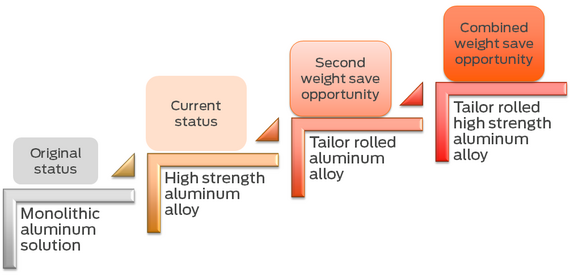

1. Motivation

The usage of Aluminum alloys has significantly increased in recent years leading to a substantial weight reduction. This weight reduction trend has to be maintained to additional light weighting technologies. Tailor rolled Blanks (TRB) offer an interesting solution through an adequate thickness distribution through the blank allowing for an optimized usage of the weight where it is requested. This technology is however restricted right now to steels. The industrial feasibility of TRB with high strength Aluminum alloys still needs to be demonstrated. In particular the solution heat treatment phase which is necessary in order to guarantee final properties needs to be demonstrated.

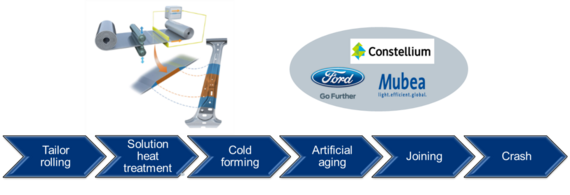

2. Project Goal

The goal of the project is the development of an industrial solution to produce tailor rolled blanks for structural body components made of high strength Aluminum alloys. Material properties should be according to Ford specifications. In this project all process steps leading to the manufacturing of Aluminum-TRB components will be verified for feasibility. One critical process step is the solution heat treatment which will enable formability and ensure required final properties.